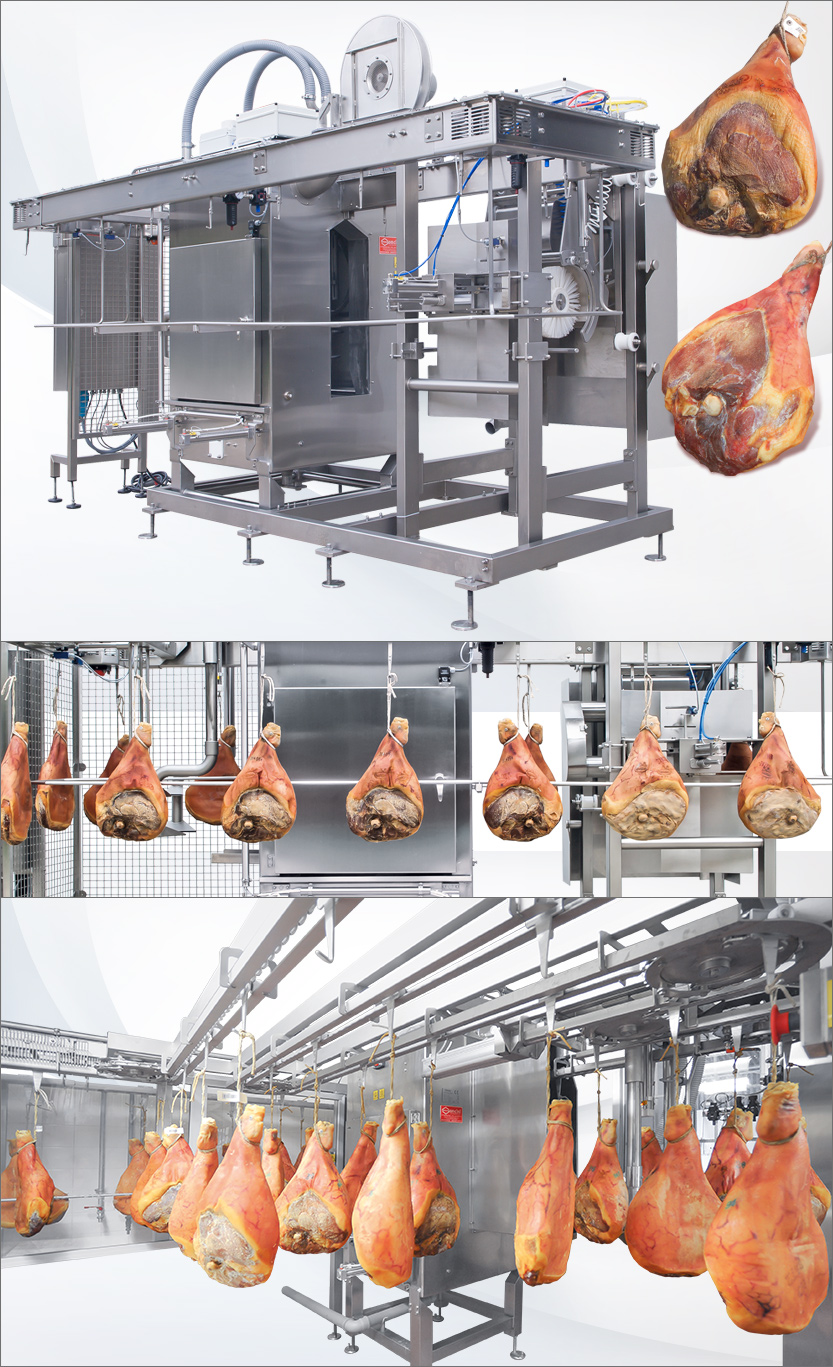

LLS143

AISI 304 stainless steel structure

Production: ~240 pieces/hour**

A new automatic line for washing and dripping of cured raw ham, speck, bacon, salted dried beef, salami, pork neck salami and similar products in transit on a dedicated chain conveyor.

The products are manually or automatically loaded onto the aerial chain conveyor line, individually washed and then unloaded in the processing area for the boning, pressing and packaging phases.

Optional: DRY BRUSHING MACHINE

A new-concept machine for dry brushing of cured raw ham and speck useful for partial suet recovery before the washing operations and subsequent boning and pressing.

Compared to normal processing with the LLS143 washing and dripping line, use of the dry brushing machine brings the following advantages:

- Reduced costs for suet recovery from the sewage.

- Reduced water consumption during subsequent washing.

- Reduced energy consumption (typically natural gas or another fuel) required to heat the washing water.

- Reduced washing times and consequently greater hourly production.

The line operates fully automatically with step-by-step or continuous forward movement with excellent results on the product and contained running costs.

Unlike conventional systems, reducing the time the product stays in contact with hot water allows maintaining the product unaltered from a physical and organoleptic point of view.

Thanks to the new dripping system, the ham can be washed and then boned straight away without having to put it in dedicated cold stores for drying.

Available in several versions designed for every system need, it can be adapted to any facility even on different levels.